Blog

Quality Isn’t It’s Own System, It Is Your Entire System!

I’ve been working with more and more companies that have “seen the light”, so to speak. Specifically, the “quality” light. And even more specifically, that operating a “quality management system” distinct from their routine operations is entirely inconsistent with the point of having a quality management system. In fact, in my experience, being able to point to your quality management system as a distinct entity is pointless.

The best way to be able to distinguish a quality management system is in the manifestations of quality in everything an operation does, not in a distinct entity. But, who could blame them? The most likely cause for this behavior are the auditors, assessors and appraisers of such systems. They frequently want to see tangible items that result from a “quality system”, and too often, they want them labeled after the names they’re used to seeing. So, naturally, organizations wanting credit for having a quality management system of a particular stripe make their efforts as obvious as possible to these outside onlookers.

I could spend trillions of electrons waxing rather unpoetically about the ills of the very people empowered to review the outputs of quality approaches being the causes of such stupid wastes of time and money, but that would certainly side-track me from my primary message in today’s post. The good news is that some operations are realizing on their own what stupid wastes of time and money such pursuits are and are seeking ways to address the quality requirements while also having a positive benefit to the company’s performance without contorting their operation to suit the idiosyncrasies of a particular third-party’s way of seeing the world.

A quality management system should show up in everything the company does. Not as a separate entity. Sure there would be some obvious, observable, tangible emissions from such a system such as reviews, problem-solving meetings, metrics, training, and so on, but for the most part, what should actually “show up” are processes, procedures, tools and resources that actually allow/cause the operation to perform well and produce a quality product or service.

The “quality management system” would be the systems thinking and the systems engineering of everything that makes the products and services of an operation come to fruition. Such a system would produce everything used and done by the company to make the company work. Being able to point to explicit things and say “that’s our quality management system” would be a lot like pointing to a single wire pulled from the engine compartment of a car and saying “that’s our vehicle”. It’s doesn’t work that way with cars or with quality.

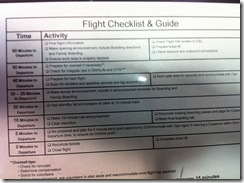

The next time I fly on Southwest Airlines, when there’s little else going on at the airport, I’ll ask a gate agent whether or not he or she knows about their quality management system. I may even ask a flight attendant the same thing before a flight. They might know. And if they do, it’s probably because of their training. But chances are, they will look at me blankly because I’m asking a ridiculous question and they are too polite to ask which planet I’m from. At Southwest, how they work is because their quality management system is what creates the work they do. It’s the epitome of quality being in everything. That’s why they are a high performance operation.

The next time I fly on Southwest Airlines, when there’s little else going on at the airport, I’ll ask a gate agent whether or not he or she knows about their quality management system. I may even ask a flight attendant the same thing before a flight. They might know. And if they do, it’s probably because of their training. But chances are, they will look at me blankly because I’m asking a ridiculous question and they are too polite to ask which planet I’m from. At Southwest, how they work is because their quality management system is what creates the work they do. It’s the epitome of quality being in everything. That’s why they are a high performance operation.

-

Entinex

A management consulting firm focused on business' performance. The recognized world expert in bringing lean principles into harmony with heavy regulations and governance. Learn More -

Agile CMMI® Blog

The blog that started a revolution. Directly from the world's recognized authority on Agile & CMMI. Learn More

Sorry, the comment form is closed at this time.